Workers’ compensation is essentially a collection of related actions taken by the employer, payer, provider and injured worker in the service of the injured worker’s recovery and return to work. Putting the injured worker at the center of this activity is critical, as discussed in the previous article in this series,

Five Best Practices to Ensure the Injured Worker Comes First. But what is the best way to achieve our objective of getting injured workers rapidly back on track? What processes, tools and systems do we put in place? What problems should we focus on?

Critical to answering these questions is a framework that is based on years of handling service operations across a range of industries (airlines, retail banking, healthcare, etc.).

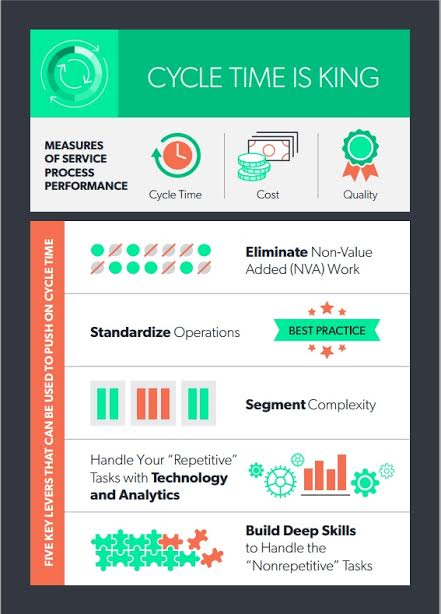

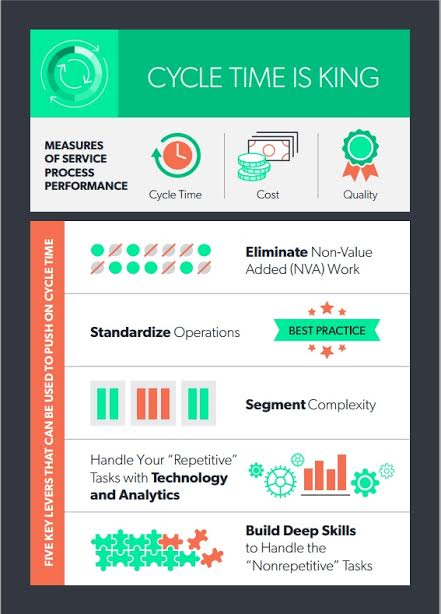

Any service process can be measured based on its performance along three dimensions:

- Cycle time — time to complete one cycle of an operation (e.g., from opening to closing of a claim).

- Cost — the cost to go through a cycle of the process.

- Quality — the error rate that occurs as you go through a cycle.

It’s a truism in process improvement that you can improve only one or two of these factors at a time, at the expense of the others. While this is true if we push on cost or quality, pushing on cycle time improves all three metrics. This is an important finding that’s worth restating. If we endeavor solely to reduce cycle time, we can improve all three metrics — cost, quality and cycle time — without sacrifice. To explain why, let’s look at a few examples.

Redesign efforts that focus on costs usually aim to increase the productivity of the current team and system. While this helps in reducing unit costs in the short term, it adds more strain on the system overall. The increased strain leads to increased error rates, which in turn leads to increased need for redundancy checking and longer cycle times. Costs start increasing as a result — the exact opposite effect of what we intended.

Redesign efforts that focus on reducing error rates typically add additional checks/rechecks in the process, leading to higher costs and longer cycle times. Once the redundancy checks are in place, it is difficult to change anything in the process because there is a fear that quality might suffer. As a result, you are stuck with a slower, costlier process.

See also: The State of Workers’ Compensation

Redesign efforts that focus on cycle time reduction push us to take a deeper look at the process. Long cycle times are typically caused by unnecessary delays in the process. In a service operations setting, delays are like inventory in manufacturing. They are in place to buffer any inefficiencies and variabilities in the essential process. Reducing delays requires us to make each step in the process more reliable and more standardized. As we do that, we strip away the layers of unused time in the process. The reduced waste lowers costs and error rates, as there are fewer failure points. The result is reduced cycle time, reduced error rates and reduced costs.

In short, if there is one thing you should focus on to improve the injured worker’s experience, it is around making the process go faster for him or her. Respect cycle time, and all else will follow.

Here are five key levers that can be used to push on cycle time:

- Eliminate non-value-added (NVA) work – Remove work that does not need to be performed and work that is not part of putting the injured worker first.

- Standardize operations – Establish best practices for straightforward tasks.

- Segment complexity – Break down your steps into “repetitive” and “non-repetitive.” Repetitive tasks are ones that can be accurately and comprehensively laid out in a flowchart. Non-repetitive tasks are ones that address a variety of cases and can’t be clearly laid out in a flowchart.

- Handle your “repetitive” tasks with technology and analytics – Automate the repetitive tasks as much as possible. They are not a good use of your team’s time. Build up your technology and analytic capabilities not only to automate these processes but also to alert you in case of exceptions.

- Build deep skills to handle the “non-repetitive” tasks – Train your team extensively to handle the complex, non-repetitive tasks (e.g., handling a complex claim heading toward attorney involvement). Use an apprenticeship-based model to train the team handling these tasks. Cross-train select staff so they can go where the need is like a SWAT team, enabling you to reach economies of scale with existing resources.

Workers’ compensation is a complex system with myriad rules and regulations that guide the provision of medical and disability benefits to injured workers. By putting the injured worker first and focusing obsessively on shaving days/minutes/seconds off the process of getting an injured worker back on track, we believe we can make a big dent in reducing the $250 billion-a-year impact of occupational injuries on the U.S. economy.

See also: 5 Best Practices on Injured Workers

Read Dr. Gardner’s first article in this series:

Five Best Practices to Ensure the Injured Worker Comes First

As first published in Claims Journal. Here are five key levers that can be used to push on cycle time:

Here are five key levers that can be used to push on cycle time: