Now that ports have been identified as the major bottleneck in the supply chain dysfunction that is slowing the economic recovery and raising prices, a Twitter connection of mine offered a novel solution:

"Assign all ships, trucks, yards, workers and rules to an app. Call it Port Simulator, and the world's 15-year-olds will have [the supply chain problem] fixed in a week or two. It is literally [the premise of] every simulation game I've ever played."

If only the answer were that simple. In fact, it now seems the supply chain fiasco will run deep into next year, putting a crimp in the plans of almost every sort of business across the globe and requiring agility by those that insure them.

In many ways, the supply chain trouble traces back decades, to companies' efforts to make production as efficient as possible, keeping the minimal amount of supplies on hand. That "just in time" approach is great -- until it isn't. And it wasn't, as of the early days of the pandemic.

As the New York Times explains the problem, "Factories in parts of the world where a lot of the globe’s manufacturing capacity sits — places like China, South Korea and Taiwan as well as Southeast Asian nations like Vietnam and European industrial giants like Germany — were hit hard by the spread of coronavirus cases. Many factories shut down or were forced to reduce production because workers were sick or in lockdown. In response, shipping companies cut their schedules in anticipation of a drop in demand for moving goods around the world.

"That proved to be a terrible mistake. Demand for some things — restaurant meals, trips to vacation destinations, spa services — indeed cratered. But Americans took the money they used to spend on such experiences and redirected it to goods for their homes, which were suddenly doubling as offices and classrooms. They put office chairs and new printers in their bedrooms, while adding gym equipment and video game consoles to their basements. They bought paint and lumber for projects that added space or made their existing confines more comfortable. They added mixers and blenders to their kitchens, as parents became short-order cooks for cooped-up children. The timing and quantity of consumer purchases swamped the system."

When factories tried to catch up with demand, the lack of shipping capacity meant that many products just piled up in warehouses, and the problems compounded from there. Truck drivers and dockworkers in the U.S. were stuck in quarantine, as dozens of ships were forced to anchor offshore Los Angeles, Oakland and other ports and wait days to unload and load again. The nearly week-long closing of the Suez Canal exacerbated the delays, as did COVID-related closings of major ports in China.

Many companies have responded to the supply chain delays by ordering extra products, adding another layer to the problem.

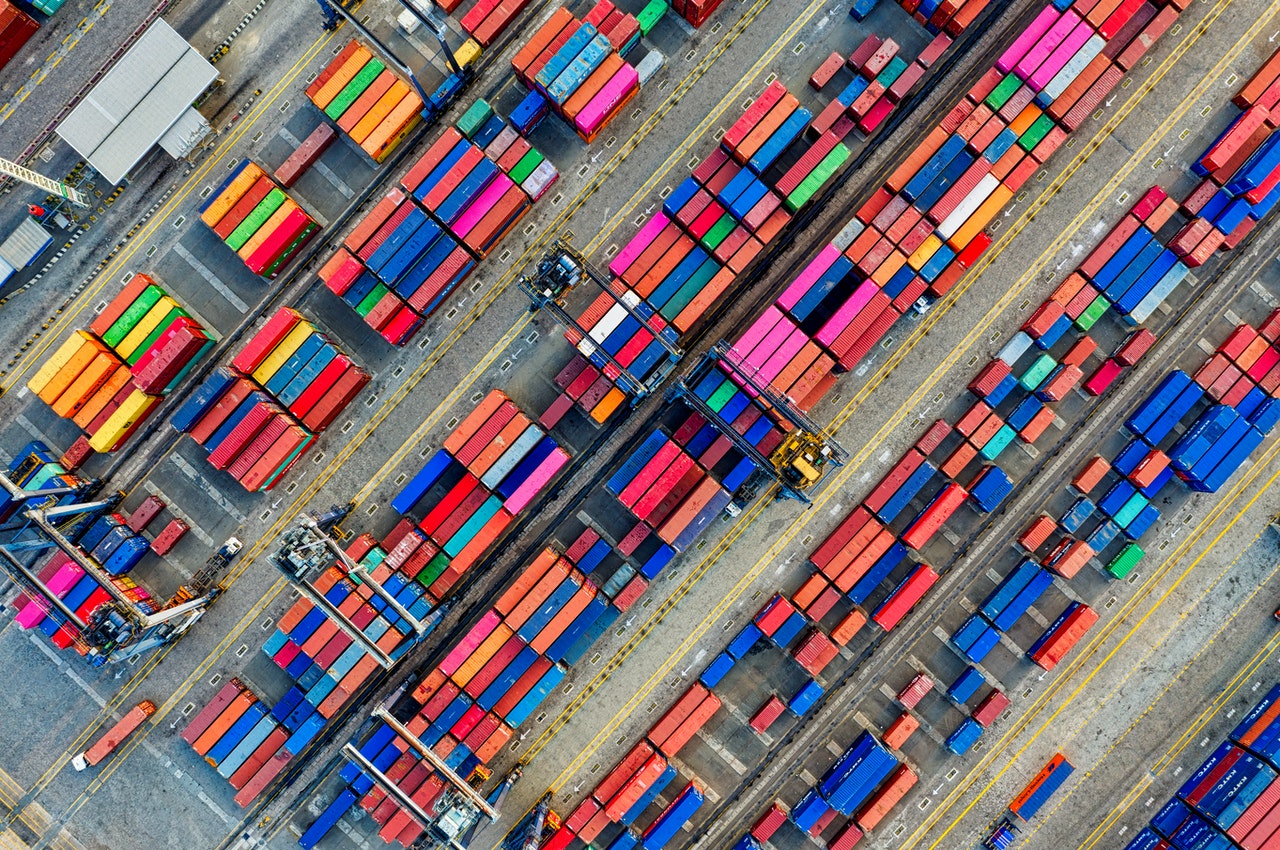

By now, we have a full-on mess, centered on a lack of available shipping containers. They are the building blocks of global shipping, and there just aren't enough of them in the right places.

Some hundreds of thousands of them, for instance, are currently sitting on 79 ships off Long Beach, Calif. (holding some $8 billion of merchandise). There are plenty of cranes available to offload the containers -- but nowhere to put them while waiting for trucks to transport them to their destinations. (Port tarmacs, usually at 60% to 80% capacity, are now at 90%, according to the Wall Street Journal.)

There aren't enough trucks to come get the containers, anyway. Because ports can't take any more containers, many trucks have nowhere to put their empties -- so containers sit idle on truck chassis, taking both the container and that chassis out of circulation.

Ryan Petersen, the CEO of Flexport, a logistics company, said he took a three-hour loop through the port of Long Beach on Thursday and, out of hundreds of cranes, counted only seven that were even operating.

"The terminals are simply overflowing with containers," he said, "which means they no longer have space to take in new containers either from ships or land. It’s a true traffic jam."

All levels of government have talked about trying to help alleviate the supply chain problems, but the efforts have mostly been talk to this point. Probably the biggest change thus far is that Long Beach will allow logistics yards to stack empty containers four or even five high, rather than the current two. Petersen says that change will "free up tens of thousands of chassis that right now are just storing containers on wheels. Those chassis can immediately be taken to the ports to haul away containers."

But tens of thousands won't solve the problem of hundreds of thousands sitting just offshore -- and with more on the way. It will likely take many months to smooth over the container issue.

In the meantime, new disruptions will arise until the pandemic finally subsides. 4.3 million Americans quit their jobs just in August, as people reevaluate career choices in what some are calling the Great Resignation. Their absence will cause pockets of issues with supply and transport. Meanwhile, more than 735,000 Americans have died from COVID, and it is still taking an average of more than 1,650 lives a day.

The supply chain issues will force major changes in how business is done. In the short term, all sorts of companies will have to adapt to shortages and come up with workarounds in transportation, factory scheduling, retailing and more. In the long run, because businesses are unlikely to go back to the super-lean approach to supplies and suppliers, at least not for the foreseeable future, they will have to rewire transportation, warehousing and logistics operations.

The changes will, of course, require adaptation both in the short run and in the long term by all those that insure these massive operations. The persistence of the supply chain issue will also create opportunities to provide risk-management expertise so that companies can be much more resilient in the face of the next global challenge than they were at the outset of this one.

In the meantime, we consumers will all just have to muddle along in the face of shortages. I don't have a 15-year-old to turn loose on the problem, but I do have a 25-year-old who is world class at Tetris. Maybe I'll get her thinking about Port Simulator and see what she comes up with.

Cheers,

Paul

P.S. Here are the six articles I'd like to highlight from the past week:

Insurtech Is Much More Than Just Hype

Despite Chubb CEO Evan Greenberg's claim that insurtech is just hype, the movement is real and important and exciting and valuable.

Boldly Insure Where No One Has Gone

Commercialization of space is a once-in-a-generation opening.

Future of Digital Insurance Claims

We could be in danger of leaving the customer out of the equation in the rush to digitize and automate insurance processes.

Lemonade's recent glitch sheds light on public fears about AI -- and about what must be done to keep AI innovation from slowing.

Long Live the Claims Adjuster!

There is tremendous momentum for leveraging technology in claims, but that does not mean the adjuster will become obsolete.

Innovation at the Point of the Customer

Innovation must focus on claimants, who deal with all sorts of requirements while going through perhaps the worst time of their lives.